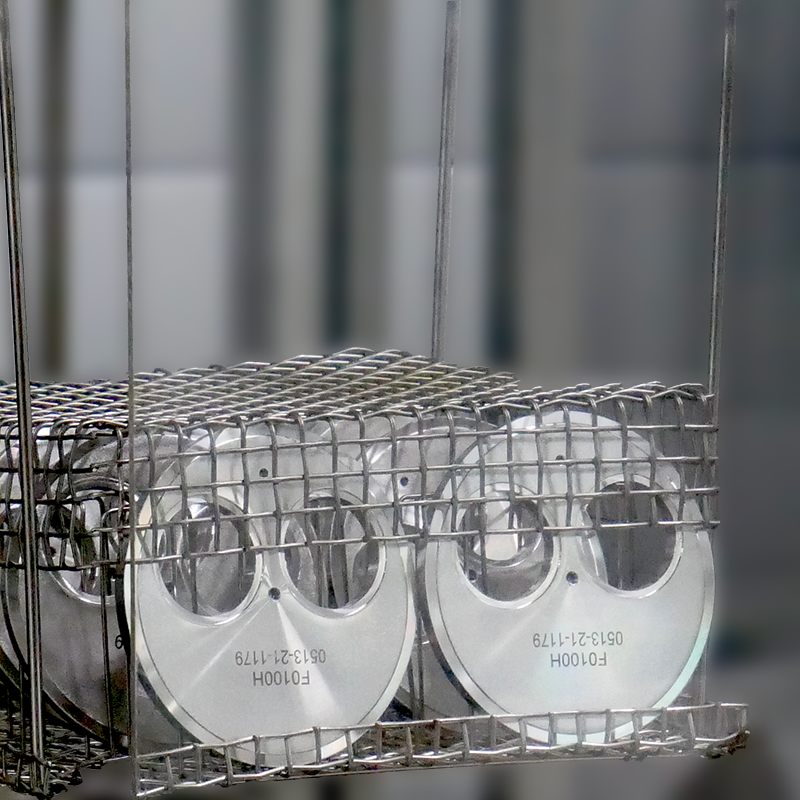

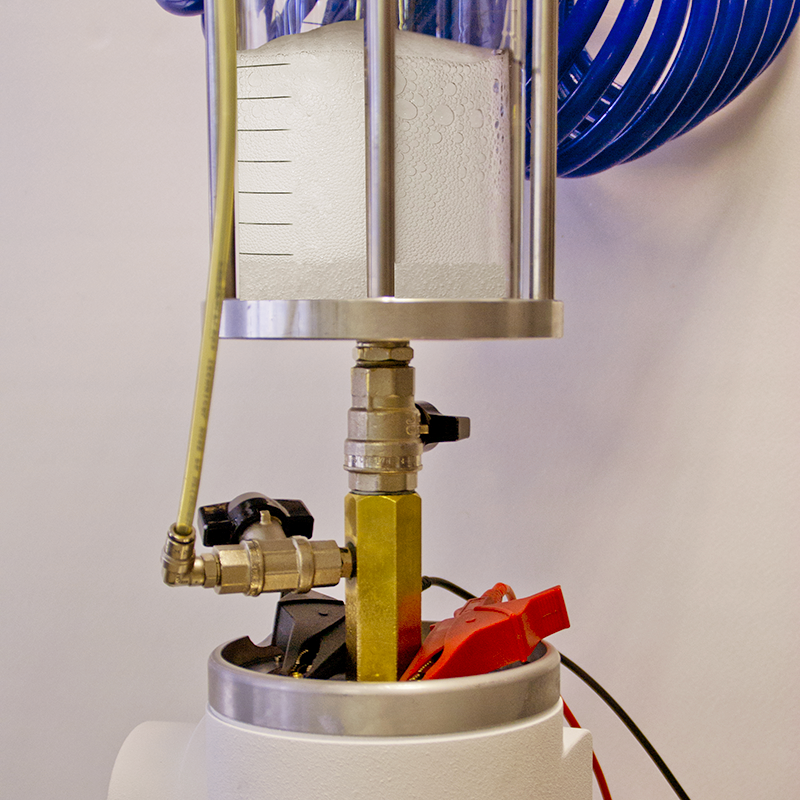

All surfaces have to be throughly cleaned from any dirt and product residual, in order to keep the highest vacuum level inside the tube during operation.

IAE has an automatic washing system, software controlled, for deep degreasing, etching and cleaning of all surfaces.

It involves the use of several different cleaning agents, such as:

· detergents

· ultrasound vibrations

· acid etching

· nitrogen drying.